Alcohol measuring instruments

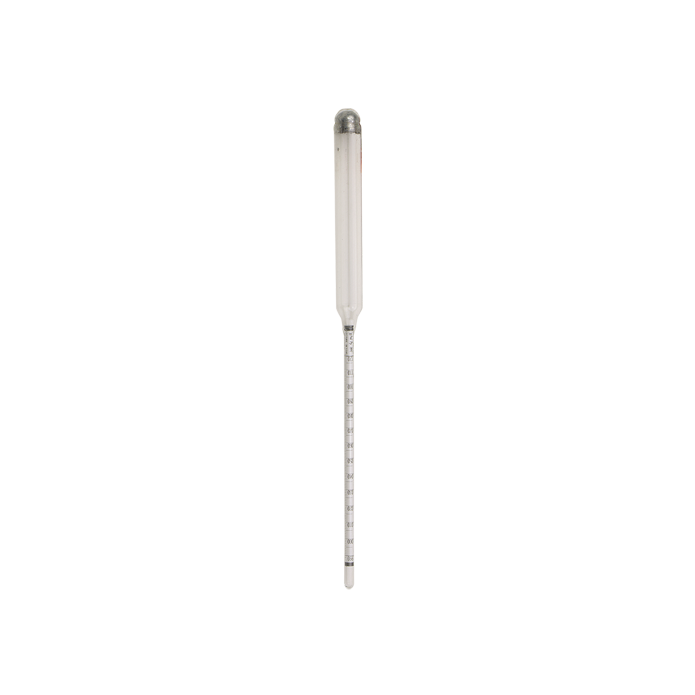

The mustimeter, alcoholmeter and cider scales are all tools used in cider and wine making to measure various parameters such as sugar or alcohol content.

The mustimeter is used to measure the density of the must, i.e. the mixture of fruit juices before fermentation. L'alcoholometer is used to measure the alcohol content of a liquid, generally after fermentation. The cider scale is used to measure the specific gravity of cider or apple must.

Why measure sugar and alcohol levels in cider?

Measuring sugar and alcohol levels in cider is essential for controlling fermentation, adjusting flavors, maintaining quality, and complying with regulations.

First of all, you need to control fermentation. The sugar content in apple must determines the amount of alcohol produced during fermentation. By measuring the initial sugar content, you can estimate the alcoholic potential of the fermented cider. This allows you to control and regulate the fermentation process to achieve the desired alcohol level.

Then you need to balance the flavors. Residual sugar in cider influences its taste and mouthfeel. A cider that's too sweet can seem unbalanced, while one that's too dry can lack body and complexity. By measuring sugar content, you can adjust fermentation to achieve the desired flavor balance.

Finally, you need to guarantee quality. Regularly measuring the alcohol content in cider enables you to maintain consistent quality from batch to batch. This ensures that your final product meets the quality standards expected by your customers, or by you as the producer.

In many countries, there are strict regulations concerning the alcohol content of alcoholic beverages, including cider. Accurately measuring and reporting the alcohol content of your cider is necessary to comply with these regulations.

The different stages in cider-making

Cider-making involves several stages, from apple selection to the bottling of the finished cider. Here are the main stages in the process:

- Apple selection: The apples used to make cider are generally specific varieties that offer a balance of acidity, sugar and tannins. Producers may use different varieties or a blend of varieties to achieve the desired flavor profile.

- Washing and crushing: Apples are washed to remove dirt and impurities, then crushed to release their juice. Crushing can be carried out using an apple crusher or a special press.

- Pressing: Apple juice is extracted from the crushed pulp using a cider press. The pressed juice is called apple must.

- Filtration: Apple must is sometimes filtered to remove unwanted solid particles. This can be done using filters or natural clarification methods.

- Yeast addition: To ferment apple must and produce cider, yeast is added. Yeast converts the sugars in the must into alcohol and carbon dioxide during the fermentation process.

- Fermentation: The fermented apple must is transferred to fermentation tanks, where it is left to ferment for several weeks to several months, depending on the type of cider and the desired flavor profile. During fermentation, the yeasts consume the sugars and produce alcohol and CO2.

- Maturation: After fermentation, cider is often left to mature for a few months to allow the flavors to develop and balance. During this period, clarification processes can also occur naturally.

- Blending (where applicable): In some cases, producers may blend different batches of cider to achieve the desired flavor profile. This may involve blending ciders of different varieties or ages.

- Bottling: Once maturation is complete, the cider is bottled. Before bottling, it may be filtered again to remove unwanted particles and ensure optimum clarity.

- Storage and aging (optional): Some ciders can be aged in bottle for a few months to several years to develop more complex flavors. Aging time depends on the style of cider and the producer's preferences.

- Marketing and tasting: Once bottled, cider is ready to be marketed and tasted. It can be sold in specialty stores, cider bars or directly from the producer.

These steps represent a general overview of the cider-making process. Specific details may vary according to the production techniques used by each producer and the type of cider made.

How to use a mustimeter ?

The various stages of measurement

To use, fill a graduated cylinder with the must to be tested. Place the mustimeter in the must. Make sure it floats freely without touching the walls of the cylinder. Read the density reading where the surface of the liquid crosses the scale. The density of wort before fermentation is usually expressed in specific units, such as degrees Brix.

How to use an alcoholometer ?

The various stages of measurement

Fill a graduated cylinder with the cider or wine sample to be tested. Immerse the alcoholmeter in the liquid and let it float freely. Make sure it doesn't touch the sides of the cylinder. Read the scale where the surface of the liquid crosses the alcoholmeter. The alcoholmeter will indicate the percentage of alcohol by volume (% vol).

How to use a cider scale ?

The various stages of measurement

Fill a graduated cylinder with the cider or must to be tested. Dip the scale into the liquid and let it float freely. Make sure it doesn't touch the sides of the cylinder. Read the scale where the surface of the liquid crosses the scale. The specific gravity of cider can be used to estimate sugar content and predict potential alcohol content after fermentation.

Using these tools, you can monitor and adjust the fermentation process to achieve the desired flavor profile in your cider or wine. Be sure to follow the specific instructions for each instrument, and take hygienic measures to avoid contamination.

In a nutshell, the mustimeter measures the density of the must before fermentation to estimate alcohol potential, the alcoholmeter measures the alcohol content in the cider after fermentation, and the cider scale measures the specific gravity of the cider during and after fermentation to monitor fermentation progress and estimate residual sugar content. Each instrument plays an important role in the cider-making process, providing crucial information for controlling fermentation and adjusting flavors.